MOSFETS differ from ordinary (Junction) FETS that in

the former the gate is physically insulated from the channel with an insulating

layer of Silicon dioxide so that no current can flow from the gate to the

channel under any circumstance.

There are two types of MOSFETs available; they are

called Depletion type MOSFETS and Enhancement type MOSFETS. The basic

structures of both types is similar except one important difference, that the

depletion MOSFET has a physically implanted channel where as in enhancement

type MOSFETS a temporary channel is induced

whenever necessary by applying an appropriate voltage between gate and the

source.

Operation

of an n-channel depletion type MOSFET

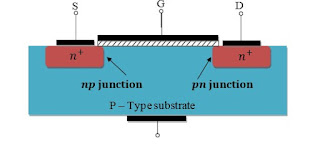

In the n- channel device shown in Figure 13, the

gate is made negative with respect to the source, which has the effect of

creating a depletion area, free from charge carriers, beneath the gate. This

restrict the depth of the conducting channel, so increasing channel resistance

and reducing current flow through the device.

Of the two the enhancement type MOSFET is the

most widely used field effect transistor, especially in digital electronics,

and therefore our discussion is restricted to the enhancement type MOSFET.

The

transistor is fabricated on a p-type substrate which is a single crystal of

silicon. Two heavily doped n-type regions indicated in the figure as n+

Source and n+ Drain regions are created

in the substrate. A thin (0.1µm) layer of silicon dioxide which is an

excellent insulator, is grown on the surface of the substrate covering the area

between the source and the drain. Metal is deposited on top of the oxide layer

to form the gate electrode of the device. Metal contacts are also formed on the

source and the drain regions and also on the substrate, also known as the body.

Now it should be clear as to why this device is called

Metal-Oxide-Semiconductor FET. Note some modern devices use poly-silicon to

form the gate electrode, but still they are called MOSFETS.

Operation

of the device with no gate voltage

|

|

and

the source. See Figure 15. One diode is formed by the n+ source and p substrate

on the LHS and the other junction by the substrate and the n+ drain junction on

the RHS. These back-to- back diodes prevent current conduction from drain to

source when a voltage VDS is applied across the drain and the

source.

Now

consider a situation where the source is grounded and a variable positive

voltage (VGS) is applied to the gate as shown in Figure 15. The

positive voltage on the gate drive away the (free) holes in the p substrate

from the region just underneath the gate. These holes are pushed down words

into the substrate leaving behind a carrier depletion region. As the gate

voltage is increased the electrons from the two n+ regions as well as from the substrate are attracted to the

region just underneath the gate inducing a temporary electron channel (n-channel) connecting the two n+ region

(i.e. source and the drain), Now if a voltage is applied between the drain and

the source, current flows through this induced n region. The induced n region

thus forms an n channel for current

flow, and hence the structure shown in Figures 14 and 15 are called n-channel MOSFETs.

The

value of VGS at which a sufficient number of mobile electrons accumulate in the

channel region to form a conducting channel is called the threshold voltage. This value typically lies in the range 1 to 3 V.

In

this process the channel created by inverting the property of the substrate

from p type to n type. Hence this induced channel is also called an inversion layer.

It

should be realized now that a p-channel MOSFET can also be

constructed in the similar way by fabricating two p+ regions and a gate in an n-type

substrate. In this case a p-channel can be formed by applying a negative VGS

voltage across gate and the source with gate negative.

No comments:

Post a Comment